Latest release provides enhanced data visualization and blockchain capabilities for verified source to store supply chain data

BOSTON, March 1, 2018 /PRNewswire/ — Transparency-One, the source to store supply chain transparency solution, has released new functionalities to arm businesses with more granular transparency and control of their supply chains. All partners in the supply chain, from raw material suppliers to consumer-facing brands, can use the Transparency-One platform to simultaneously manage supply chain mapping, compliance, and sustainability data as well as batch and purchase order (PO) traceability information for increased accuracy.

Targeted Transparency: Data Granularity at the Right Level for Every Supply Chain

Transparency-One has expanded its data analytics to include product transactions such as batches, lots, and POs. This new optional capability enables companies to integrate their existing ERP data with Transparency-One’s supply chain mapping platform to increase visibility for their most critical supply chains.

With Transparency-One’s latest release, users now have the ability to:

- Interface with PO and production systems at all levels in the supply chain

- Track batches and POs by product, from source to store

- Search on specific batches or POs and assess impact on finished goods products

The Transparency-One solution supports GS1’s GTIN, GPC, and GLN standards to ensure supply chain partners around the world can collaborate and share information in a single platform.

Users can choose their desired level of granularity not just for each supply chain but for each individual component. Companies can track specific batches or POs for their most critical components or ingredients, while managing other suppliers at a component level. This approach makes it possible to onboard the entire supply chain, without requiring suppliers of less critical raw materials to share batch or PO-level information.

Actionable Insights from Supply Chain Transparency Data

The ability to combine transactional data with supply chain mapping enables business to do more with their existing data. By incorporating ERP data into Transparency-One’s supply chain mapping platform, users can dive deep into a single batch or PO as well as gain a broader view of their global supply chains, for a full range of control.

- Achieve more efficient recalls and proactive risk management: For example, rather than pulling all products containing contaminated milk coming from a specific supplier, only those products impacted by the specific batch of contaminated milk will be recalled. Users can also leverage Transparency-One’s supply chain mapping abilities to proactively manage potential risks by identifying other milk suppliers in the same geographic region.

- Analyze critical raw material impact and supplier compliance: For example, textile companies can analyze, at the PO-level, the country of origin of cotton in a specific finished good to ensure compliance. They can then use Transparency-One’s supply chain mapping to identify which of their suppliers meet their quality requirements and make adjustments as needed.

- Anticipate potential issues with big data: Mass data collection at the batch or PO-level enables businesses to detect issues by checking dates as well as comparing input and outputs.

- Communicate verified information to consumers: Share insights with shoppers based on compliance information throughout the supply chain

By leveraging all information available, whether batches, POs, or supply chain mapping, companies can reduce the impact of a crisis, respond more efficiently, and manage risk proactively.

A Pragmatic Approach to Blockchain

All information entered in the Transparency-One platform can be added to the blockchain to create an immutable record of supply chain data, via a strategic partnership with Microsoft. Transparency-One has opted for a hybrid approach: the blockchain database is centralized, but with decentralized ownership. Each supplier who adds their data to the blockchain maintains ownership of their information; other supply chain partners can also blockchain their data, using the information shared by other suppliers, while still maintaining data ownership. This brings the power of blockchain through Transparency-One’s scalable platform.

Building upon the Transparency-One solution’s existing blockchain functionalities, batch lot and PO information can also be added to the blockchain for additional data security. Once added, it is permanently recorded and cannot be modified or deleted. Any additional interactions involving this lot or PO are added as additional transactions in the blockchain, which in turn become immutable. In this way, blockchain further enhances the security of supply chain data stored in the Transparency-One platform.

In addition, all supplier certifications added to the Transparency-One platform are verified by SGS, the world’s leading inspection, verification, testing and certification company. With over 95,000 employees, SGS operates a network of over 2,400 offices and laboratories around the world to provide global verification services—a critical step for ensuring the quality of the data pushed to the blockchain.

Benefits for All Supply Chain Stakeholders

The Transparency-One solution has implemented new capabilities to help stakeholders along the entire supply chain ensure regulatory compliance. All supply chain partners, from raw material suppliers to brand owners, can use the Transparency-One platform to:

- Manage and monitor critical supply chain data: Track social, safety, and sustainability information in a centralized database and define necessary documentation to ensure compliance with regulatory, market, and customer requirements.

- Gather business-specific data: Send custom surveys to suppliers to collect additional data on environmental practices, anti-modern slavery measures, etc.

- Assess supply chains at a glance or dive deep for in-depth analysis: View map visualizations of complete supply chains and explore detailed dashboards on supply chain mapping progress, compliance, modern slavery risk, and more.

- Create custom dashboards: Customize business intelligence dashboards to analyze supply chains within a business-specific framework, such as tracking progress towards sustainability goals.

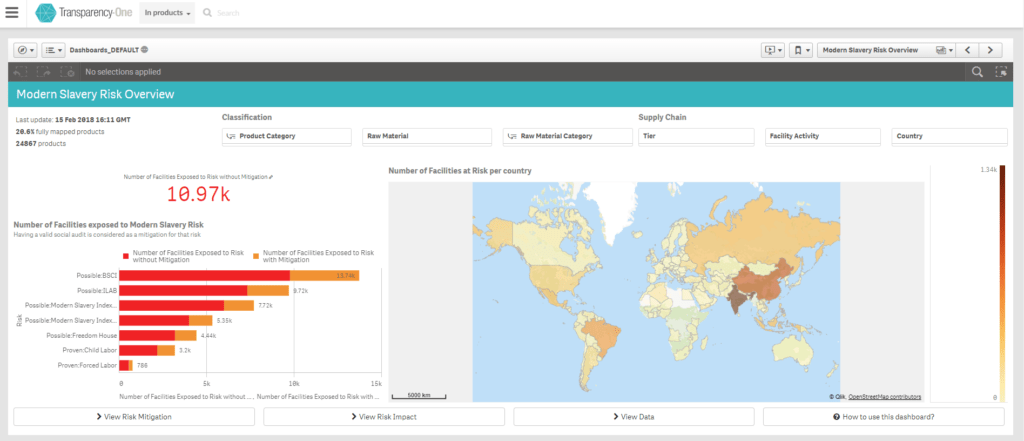

Transparency-One’s Modern Slavery Risk Dashboard

Transparency-One to Speak at the Global Food Safety Conference (GFSC)

Transparency-One is a proud sponsor of the Consumer Goods Forum’s Global Food Safety Conference 2018, taking place next week in Tokyo, Japan.

“GFSC is always an exciting event bringing together some of the biggest names in the food industry,” said Chris Morrison, Chief Executive Officer of Transparency-One. “We are proud to share how our platform’s newest developments can provide an in-depth, full-scale solution for supply chain transparency and traceability.”

Morrison will participate in a panel on Big Data and Blockchain at GFSC on March 7.

About Transparency-One

Transparency-One enables companies to discover, analyze, and monitor all suppliers, components, and facilities in the entire supply chain. Transparency-One combines cutting-edge graph database technology, supply chain expertise, and global supplier onboarding services, in partnership with SGS, to help all supply chain stakeholders reduce business risk. The company is based in Boston, Massachusetts with offices in Paris, France.

https://www.transparency-one.com

About SGS

Transparency-One has partnered with SGS to ensure safe supply chains. SGS is the world’s leading inspection, verification, testing and certification company. SGS is recognized as the global benchmark for quality and integrity. With more than 95,000 employees, SGS operates a network of over 2,400 offices and laboratories around the world.

http://www.sgs.com/en/agriculture-food/food/transparency-one

This article was originally published on PR Newswire on March 1, 2018.