W e believe there is a fundamental shift happening towards greater corporate social responsibility and sustainability.

e believe there is a fundamental shift happening towards greater corporate social responsibility and sustainability.

Evidence of this shift is plentiful. Of course, consumer demand for sustainable and ethical products—and the corporate sustainability commitments that have arisen as a result—indicate the importance of responsible sourcing. However, the investment community’s increased emphasis on Environmental, Social, and Corporate Governance (ESG) is strong evidence of just how fundamental this shift is.

What is ESG?

ESG helps investors better understand the sustainability and societal impact of a business to determine a company’s current valuation and future financial performance. ESG investing has grown dramatically in the past several years. According to McKinsey research, “global sustainable investment now tops $30 trillion—up 68 percent since 2014 and tenfold since 2004.”

In short, it is no longer just about maximizing profits, but also about prioritizing sustainable supply chain practices to ensure long-term growth and longevity. The rise of ESG points to a fundamental new way of doing business.

A perspective on ESG and the global supply chain

Ten years ago, consumers started asking for greater supply chain transparency. Today—especially given the striking events of the past 9 months—it is becoming mandatory. Transparency is linked to trust, and consumers want to trust the companies they buy from.

From an ESG perspective, the supply chain represents the largest potential ESG risk for most companies, yet the biggest area to make a positive impact. Companies shifting how they buy can fundamentally change the world.

Digital supply chain platforms have disrupted many parts of the economy, but most large companies procure and source the same way they have for decades. Our mission is to accelerate the shift to responsible sourcing. What does this really mean?

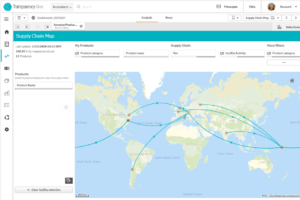

Most companies typically only know their direct suppliers. Critical information to manage risks, assure supply chain resilience, and create positive impact lies in the lower supply chain tiers. Lifting this “visibility barrier” is the key to making an exponential impact.

For example, one direct supplier may be linked to 1000 sub-tier suppliers. Legacy business processes and especially ERP systems consider one tier, not the extended supply chain. Our mission is to help companies make the shift to considering the extended global supply chain.

Five FAQs about supply chain transparency

1. How big are these supply chains?

The answer is Big. In the food industry, you might see 1,500 farms connected to just one single supplier. In the apparel industry, a single season of shirts may involve five tiers, 60+ suppliers, and 15 countries. Looking at these numbers, the likelihood of risk is substantial—but with this complexity, even small changes can have a very real impact.

2. How do companies manage this today?

Most often, they do not. Most companies have multiple systems just to manage their direct suppliers. One of our customers had to use 6 different systems and 10 different spreadsheets that captured information across all compliance, CSR, and sustainability criteria. It would take days to have a consolidated view for one supplier, now they can see a profile in one second.

If we want to assess and manage multiple tiers, it is unsustainable to do this manually on a spreadsheet. The big ERP systems were not designed to work multi-tier; this technology just did not exist until just a few years ago.

We now can map entire supply chains and in one second see the standards and compliance through that supply chain.

3. Why would suppliers respond, and will they share information?

Working with thousands of suppliers, we have seen that very few, if any, suppliers don’t respond. In fact, we often hear from suppliers that they are asked over and over for the same information, so digitizing this information has a big benefit for everyone. Typically, we see this average:

- 70% of suppliers provide complete visibility to their sub-tier suppliers

- 20% of suppliers provide partial visibility. The main area that is hidden is the name of their sub-tier suppliers. This means the buyer knows the supplier and their suppliers are meeting their standards, but it protects the supplier’s business relationship. This is a pragmatic point for adoption.

- 10% refuse all together

4. What happens with the data once they have it?

We see three actions companies can take:

- Fix non-compliances: For example, in organic products, find what percent of the extended supply chain is not certified for organic, and monitor and request the certification.

- Support supplier sourcing decisions: One major consideration in supplier selection and negotiation is their risk level from CSR and compliance. For example, a company shifting to sustainable fiber is now able to buy from those suppliers whose entire supply chain is certified. This is also a powerful differentiation for the supplier.

- Mitigate environmental risks: We find that 5% to 20% of facilities and farms are in a high-risk zone, such as for deforestation, water stress, social risk, or protected lands. Businesses can identify these risks and work with their supplier to find new farms, or target mitigation programs like training or equipment investments.

5. How do consumers react?

We have run tests with “product journey” data presented to consumers in-store through mobile apps or augmented reality.

- 70% of consumers wanted to know where their product came from

- 1/3 of consumers felt increased confidence in the product and increased their propensity to buy

- 80% of consumers became aware of the brand’s sustainability efforts

The overall net impact was very positive of both building trust and correlating the link to revenue

How Transparency-One helps

Transparency-One is a technology company providing a platform for responsible sourcing. Our digital supply chain solution does four things:

Transparency-One is a technology company providing a platform for responsible sourcing. Our digital supply chain solution does four things:

- Digitize all information about the global supply chain from finished good to raw material. Our platform allows companies to interact with one another like a social network.

- Consolidate all compliance, CSR, and environmental data about the supply chain in once place, supporting “big data” analytics. Each company has different standards, which can vary drastically by commodity. For example, the risks and impacts of palm oil are different than dairy.

- Help companies monitor their supply chain to assure it meets their standards. Alerts if a supplier, anywhere is out of compliance say for an audit or certification.

- Help companies identify risks – through using satellite and geolocation data we can identify which factories, farms, or mills are creating an adverse environmental risk or may be susceptible to forced labor.

We work with large global brands across multiple industries including apparel, food, and cosmetics. We have thousands of suppliers—from large manufacturers to small farms—on the platform.

We have proven supply chain transparency is attainable and valuable. We believe we are just at the beginning of a wave of change.